Research

We work on various solidification and phase transformation problems listed below (but not limited to):

| Directional solidification | Additive manufacturing | Precipitation | Organic Photovoltaics | Atomization |

|---|---|---|---|---|

|

Experimental and computational studies in:

|

|

|

|

|

We are not limited to above areas and are open to work in other areas of phase transformations including polymers, electrostatics, magnetism, etc. based on funding and student’s interest.

| Computational Facilities | Experimental Facilities |

|---|---|

|

High-Performance Computing Clusters:

Softwares available/used:

Access to Supercomputing facilities like NSM Param Pravega and RNC Cluster at SERC, IISc |

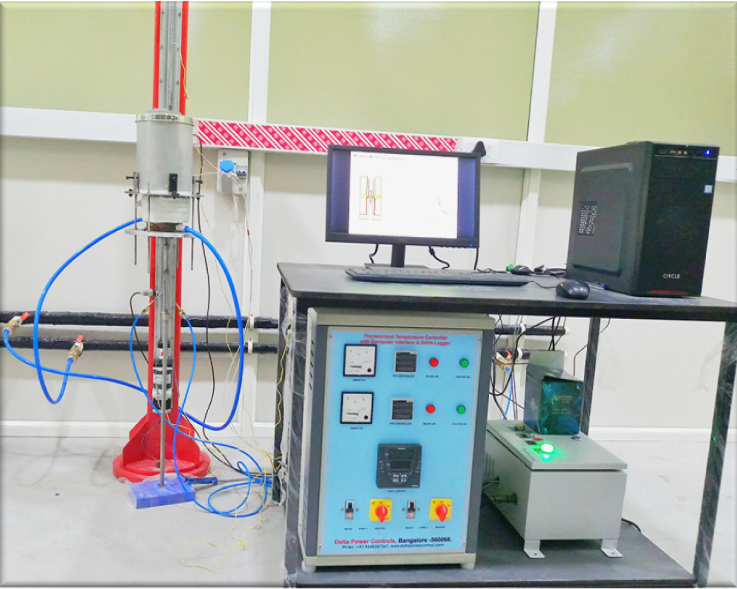

Bridgman furnaces:

Access to department and AFMM microsopy facilities |

Software Development

Our group is one of the core contributors to MicroSim, an open-source Microstructure Simulation software stack. The software is being developed under the Nation Supercomputing Mission, Government of India and available on GitHub. Previous workshop videos are available on our YouTube channel.